Product description

DNS □ □ – M1L semiconductor equipment protection fuse, suitable for DC systems, with a rated voltage of 800V and a rated current of 35A~800A, used for short-circuit protection of semiconductor components and their complete equipment.

All performance indicators of the product comply with GB/T 13539.4/IEC 60269-4

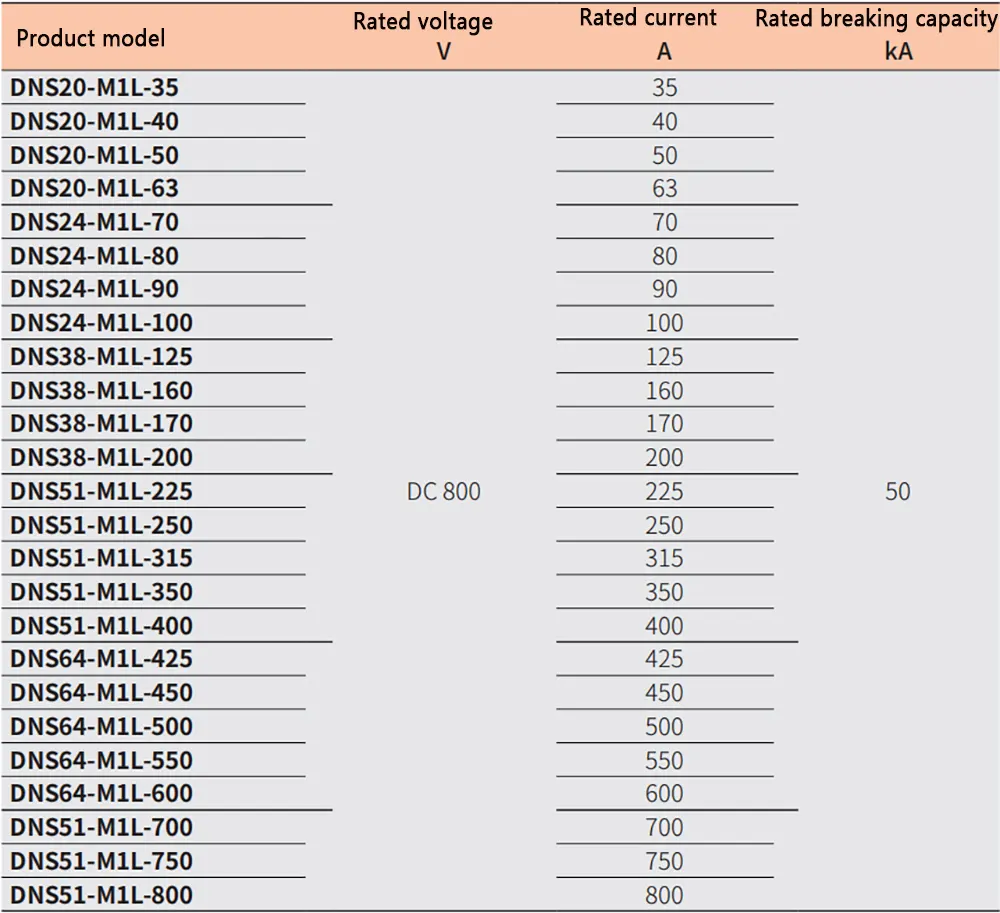

Basic parameters of fuse links

| Product model | Rated voltage V | Rated current A | Rated breaking capacity kA |

| DNS20-M1L-35 | DC 800 | 35 | 50 |

| DNS20-M1L-40 | 40 | ||

| DNS20-M1L-50 | 50 | ||

| DNS20-M1L-63 | 63 | ||

| DNS24-M1L-70 | 70 | ||

| DNS24-M1L-80 | 80 | ||

| DNS24-M1L-90 | 90 | ||

| DNS24-M1L-100 | 100 | ||

| DNS38-M1L-125 | 125 | ||

| DNS38-M1L-160 | 160 | ||

| DNS38-M1L-170 | 170 | ||

| DNS38-M1L-200 | 200 | ||

| DNS51-M1L-225 | 225 | ||

| DNS51-M1L-250 | 250 | ||

| DNS51-M1L-315 | 315 | ||

| DNS51-M1L-350 | 350 | ||

| DNS51-M1L-400 | 400 | ||

| DNS64-M1L-425 | 425 | ||

| DNS64-M1L-450 | 450 | ||

| DNS64-M1L-500 | 500 | ||

| DNS64-M1L-550 | 550 | ||

| DNS64-M1L-600 | 600 | ||

| DNS51-M1L-700 | 700 | ||

| DNS51-M1L-750 | 750 | ||

| DNS51-M1L-800 | 800 |

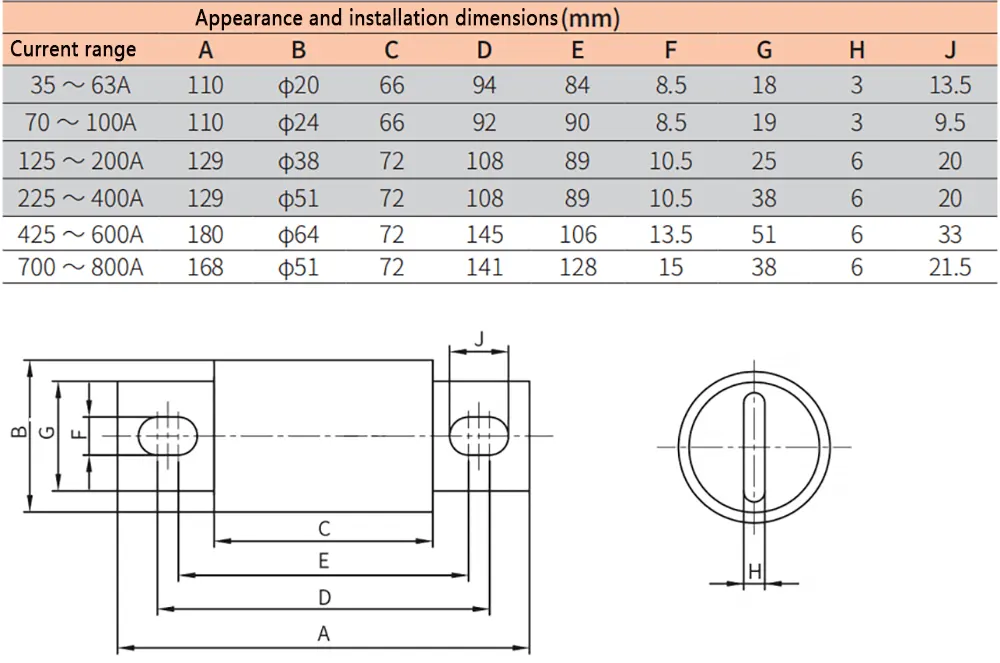

Appearance and installation dimensions

What are the latest innovations in semiconductor fuse technology?

The semiconductor fuse technology had been evolving with several innovations aimed at enhancing performance, reliability, and application-specific functionalities. These advancements reflect the growing demands of modern electronic and electrical systems, particularly in industries like renewable energy, electric vehicles, and high-speed computing. Here are some of the latest innovations in semiconductor fuse technology:

- Enhanced Materials

High-Performance Conductive Materials: Research and development in advanced conductive materials, including composites and alloys, have led to fuses with better conductivity, lower heat generation, and improved overall efficiency.

Improved Arc-Quenching Materials: Innovations in arc-quenching materials help in quicker and safer interruption of overcurrents, especially critical in high-voltage DC applications like electric vehicles and renewable energy systems.

- Miniaturization

Compact Designs: With the trend of miniaturization in electronics, fuses are becoming smaller while still maintaining or even increasing their current and voltage handling capabilities. This is particularly important in applications like consumer electronics and IoT devices.

Surface-Mount Technology (SMT) Fuses: Advances in SMT fuses allow for direct mounting on PCBs, saving space and improving performance in compact electronic devices.

- Smart Fuses

Integration with Sensors and IoT: Some semiconductor fuses are now being integrated with sensors that can provide real-time data on current, voltage, and temperature. This data can be used for predictive maintenance and to improve system reliability.

Communication Capabilities: Fuses with built-in communication capabilities can interface with control systems or IoT networks, enabling remote monitoring and control.

- Application-Specific Innovations

EV-Specific Fuses: With the rise of electric vehicles, there’s been a focus on developing fuses that can handle high voltages and currents, rapid charge/discharge cycles, and are resistant to vibration and thermal cycling.

Renewable Energy Fuses: Fuses designed specifically for solar panels, wind turbines, and battery storage systems, capable of handling unique challenges like fluctuating current levels and environmental exposure.

- Improved Safety Features

Blow-Indicator Fuses: These fuses include an indicator pin or flag that pops up when the fuse blows, making it easier to identify and replace blown fuses, crucial in complex systems with multiple fuses.

Non-Explosive Designs: For high-power applications, fuses are being designed to operate without explosive rupture under fault conditions, enhancing safety.

- Environmental Sustainability

Eco-Friendly Materials: The use of lead-free and other environmentally friendly materials in fuse manufacturing is growing, driven by regulations and sustainability goals.

Recyclability: There’s an increasing focus on making fuses more recyclable, in line with global trends towards reducing electronic waste.

Conclusion

The semiconductor fuse industry is continually innovating to meet the evolving needs of modern technology and infrastructure. These advancements not only aim at improving electrical performance and safety but also at ensuring compatibility with the latest trends in electronics design and sustainable practices. As technology continues to advance, we can expect to see further innovations in this field, particularly in areas like smart functionality, materials science, and application-specific design.

Click to view grl group company information>>

Click to view grl fuse link product>>

Click to view fuse base product>>

Click to view fuse holder product>>

leave your question

Get your Comfortable Solution

![]()

GRL Electric Co., Ltd. is one of the leading companies in the Middle And High End market of low-voltage electric in China