Product description

The DNT □ – R1R series semiconductor equipment protection fuse is suitable for AC systems, with a rated voltage of 1300V and a rated current of 160A~1250A. It is used for short-circuit protection of semiconductor components and their complete equipment.

All performance indicators of the product comply with GB/T 13539.4/IEC 60269-4.

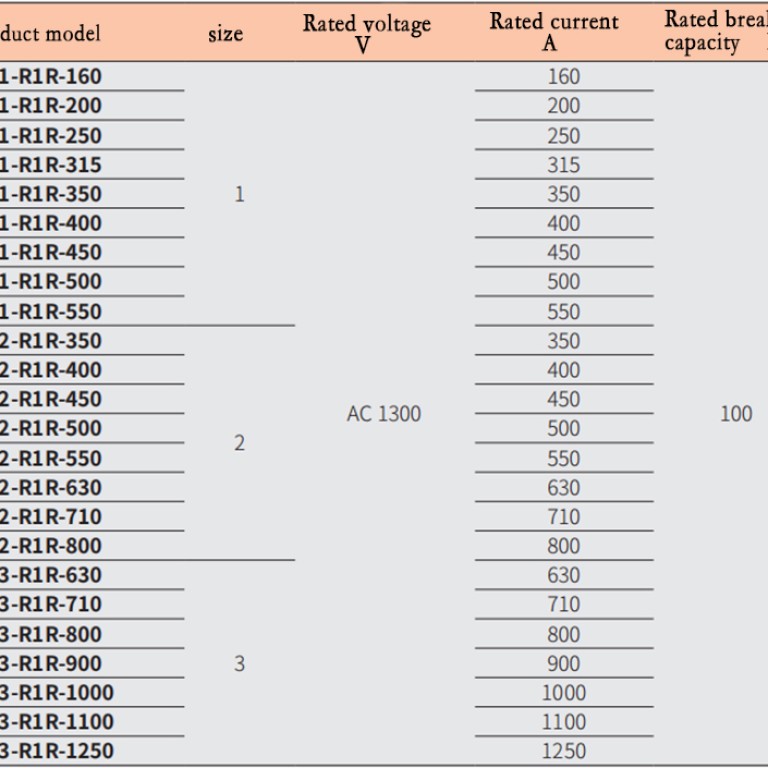

Basic parameters of fuse links

| Product model | size | Rated voltage V | Rated current A | Rated breaking capacity kA |

| DNT1-R1R-160 | 1 | AC 1300 | 160 | 100 |

| DNT1-R1R-200 | 200 | |||

| DNT1-R1R-250 | 250 | |||

| DNT1-R1R-315 | 315 | |||

| DNT1-R1R-350 | 350 | |||

| DNT1-R1R-400 | 400 | |||

| DNT1-R1R-450 | 450 | |||

| DNT1-R1R-500 | 500 | |||

| DNT1-R1R-550 | 550 | |||

| DNT2-R1R-350 | 2 | 350 | ||

| DNT2-R1R-400 | 400 | |||

| DNT2-R1R-450 | 450 | |||

| DNT2-R1R-500 | 500 | |||

| DNT2-R1R-550 | 550 | |||

| DNT2-R1R-630 | 630 | |||

| DNT2-R1R-710 | 710 | |||

| DNT2-R1R-800 | 800 | |||

| DNT3-R1R-630 | 3 | 630 | ||

| DNT3-R1R-710 | 710 | |||

| DNT3-R1R-800 | 800 | |||

| DNT3-R1R-900 | 900 | |||

| DNT3-R1R-1000 | 1000 | |||

| DNT3-R1R-1100 | 1100 | |||

| DNT3-R1R-1250 | 1250 |

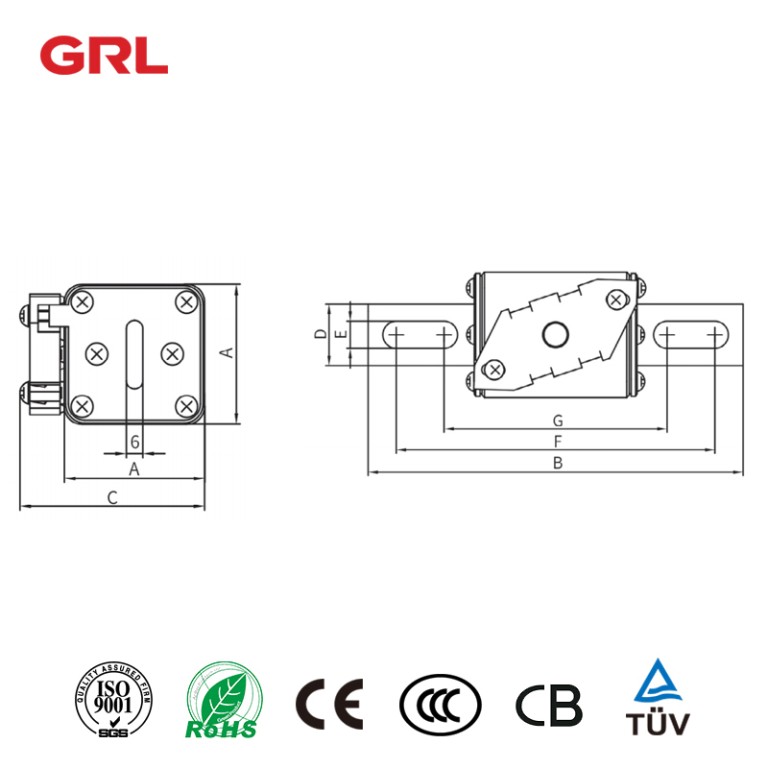

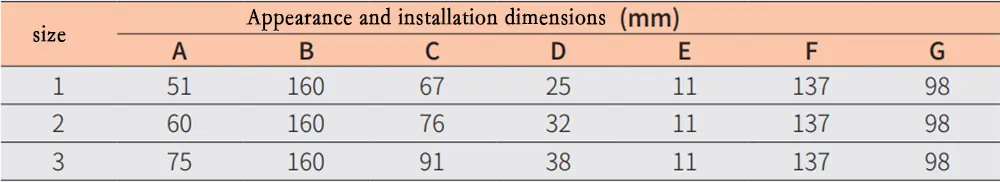

Appearance and installation dimensions

What case studies or industry examples can be showcased to demonstrate the reliability of semiconductor fuses?

Specific case studies or industry examples that demonstrate the reliability of semiconductor fuses are typically proprietary or not widely publicized in detail for general consumption. However, several industry scenarios can be outlined to illustrate how semiconductor fuses contribute to system reliability and safety. These scenarios are based on common applications and practices in industries where the reliability of semiconductor fuses is critical:

- Data Center Power Management

Scenario: A major data center operator implements semiconductor fuses in its power distribution units (PDUs) and UPS systems.

Outcome: The fuses provide rapid response to overcurrent conditions, preventing potential damage to servers and other critical equipment. In one instance, a power surge caused by an external grid fault triggered the fuses, isolating the problem and allowing the majority of the data center to continue operating uninterrupted. This quick action prevented extensive equipment damage and data loss.

- Electric Vehicle (EV) Battery Management System

Scenario: An electric vehicle manufacturer incorporates semiconductor fuses into the battery management system of its EVs.

Outcome: The fuses protect against overcurrents and short circuits within the high-capacity lithium-ion battery pack. On one occasion, a fuse successfully interrupted a potentially dangerous fault within a battery cell, preventing a thermal runaway condition and potential battery fire, thereby ensuring passenger safety.

- Renewable Energy Systems

Scenario: A solar power installation uses semiconductor fuses in its inverter systems.

Outcome: The fuses protect against faults caused by external factors like lightning strikes or internal component failures. Following a lightning strike that induced a power surge, the semiconductor fuses in the inverters operated correctly, preventing damage to the expensive inverter systems and maintaining the operational integrity of the solar panels.

- Medical Equipment in Hospitals

Scenario: Semiconductor fuses are integrated into critical medical equipment, such as MRI machines or heart monitors.

Outcome: In a hospital, a fuse in an MRI machine successfully interrupts a circuit when a power supply fault occurs, protecting the sensitive electronics. This rapid response prevents more extensive damage to the machine, allowing for a quicker repair turnaround and ensuring it is available for patient diagnostics with minimal downtime.

- Industrial Automation Systems

Scenario: A manufacturing facility uses semiconductor fuses in its robotic assembly lines.

Outcome: The fuses protect against overcurrents due to short circuits or overloads, preventing damage to expensive robotic equipment and control systems. This protection minimizes downtime and maintains production efficiency, demonstrating the fuse’s role in safeguarding industrial equipment.

Key Takeaways from These Scenarios:

Prevention of Equipment Damage: Semiconductor fuses quickly interrupt power during overcurrent conditions, preventing damage to sensitive and expensive equipment.

Safety Enhancement: In applications like EVs and medical equipment, the fuses significantly enhance safety by preventing electrical hazards.

Operational Continuity: By isolating faults, semiconductor fuses enable the rest of the system to continue operating, which is crucial in environments like data centers and hospitals.

Cost Savings: The prevention of major failures and the associated downtime leads to significant cost savings and operational efficiencies.

Click to view grl group company information>>

Click to view grl fuse link product>>

Click to view fuse base product>>

Click to view fuse holder product>>

leave your question

Get your Comfortable Solution

![]()

GRL Electric Co., Ltd. is one of the leading companies in the Middle And High End market of low-voltage electric in China