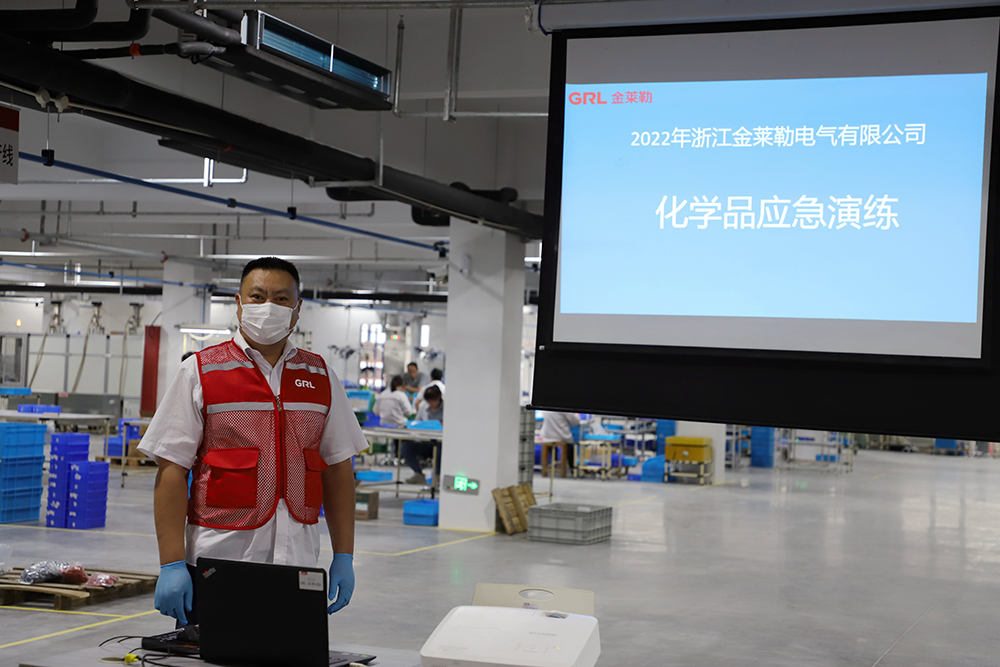

GRL conducts chemical spill emergency drill

In order to further popularize chemical safety knowledge, conscientiously implement the company’s chemical safety management,emergency drill

and improve employees’ ability to deal with and deal with hidden dangers caused by chemical leakage, our company organized a chemical emergency drill on May 26.

This chemical drill is divided into two parts: chemical knowledge popularization and simulated chemical leakage emergency drill.emergency drill

Zhang Baiwu, director of the metalworking workshop, explained the importance of safe storage of chemicals in the company in detail through simple and easy-to-understand language based on actual cases,

and popularized the basic knowledge of chemicals used by the company, leakage emergency, safe handling, etc. content, while demonstrating the process steps on how to deal with spilled chemicals.emergency drill

Afterwards, everyone went outside the fire escape for a chemical emergency drill.

Exercise content: Leakage accident of wire-cut emulsified oil drum

1.Description of the exercise process:

At 15:30 on May 26, 2022, according to the contents of “Chemical Management and Control Procedures” and “Hazardous Chemicals Safety Management Operation Instructions”,

on-site training and guidance were given to the personnel participating in the exercise, as well as chemical MSDS. Contents for publicity and matters needing attention in the exercise process.

At 15:40, the warehouse clerk cut the oil leakage accident of the emulsified oil barrel online,

and the on-site staff urgently removed the nearby items that might move, and reported to the department leader through the walkie-talkie, and then communicated according to the “emergency contact form”. Notify the office.

Within 10 minutes, the safety supervisor led the plugging team to put on rescue clothes and rushed to the accident site. At 15:50, when the alarm bell was activated, the exercise officially started.

The emergency evacuation team quickly and orderly organized the idle personnel to follow the pre-drilling exercise. The plan was quickly evacuated from the site.

Zhang Baiwu and Zhou Huijun of the leakage treatment team quickly put on protective equipment and used special plugging tools to stop the leakage of the chemical to prevent it from continuing to leak.

Feng Zhengxiang and Cheng Yi wearing protective equipment collected the leaked material in the cofferdam and placed it in a special container.

Contaminated water is collected in clean oil drums for safe disposal and transfer. The on-site first aid team and fire extinguishing team are on standby.emergency drill

2. Evaluation summary of chemical spill drills:

This exercise is mainly designed for chemical operations, chemical storage and other related personnel. More than 20 people participated in this exercise.

The chemical warehouse center warehouse staff, production workshop material staff, production workshop operation process staff, chemical warehouse management personnel, etc. all participated in the chemical leakage drill.

The chemical leakage emergency drill team held a fire drill work arrangement and specific implementation for this drill, clarified the individual position and responsibilities of each team, and repeatedly emphasized the importance of this drill and the participation of each participant in this drill.

The role played. The closeness of the plan we make is directly related to whether it is safe to deal with similar emergencies in the future.

The whole process took 30 minutes. After the exercise, the leader of the emergency team and the instructor explained to the participants the role and operation of equipment,

facilities and fire protection, the characteristics of chemicals and precautions for emergency treatment, the use of fire-fighting equipment and chemical At the same time, the irregular operations during the exercise were re-drilled,

and the relevant personnel carried out simulated operations until they fully understood, so that everyone knew about it, informed everyone, and conducted spot checks to participate in the exercise.

The personnel of the exercise conducted an oral assessment on the content of MSDS to ensure that chemical users and chemical management personnel have a comprehensive understanding of the content of MSDS.

To prevent chemical leakage before it happens, we can make our work and living environment safer only if we know how to prevent it. Although the exercise has passed, we are left with endless thinking.

For the property safety of all the company’s personnel, the company needs to organize more similar exercises, and strengthen the promotion of relevant protection and handling knowledge, so that all employees have a stronger awareness of vigilance.

This exercise has exercised the employees’ ability to deal with chemical leakage accidents in their daily work. Through the exercise, the employees’ understanding has been deepened,

the safety knowledge has been greatly improved, and the safety awareness of the alarm bells ringing in the hearts of employees has been enhanced. Safety education class.

3. Exercise improvement measures:

There were no casualties in this exercise, but there were irregularities in operation during the exercise.

In the future, regularly organize chemical leakage drill knowledge training and related MSDS content training for material department personnel and drillers.

Safety is no small matter. In order to provide customers with a safer service environment and maximize the protection of personal and property safety, our company has formulated emergency response plans and drills, carried out actual combat drills,

and continuously improved emergency response capabilities through this drill. adhere to the principle of prevention, eliminate potential safety hazards, strengthen preventive measures, and ensure the safe, stable and orderly development of the company.

View grl group information