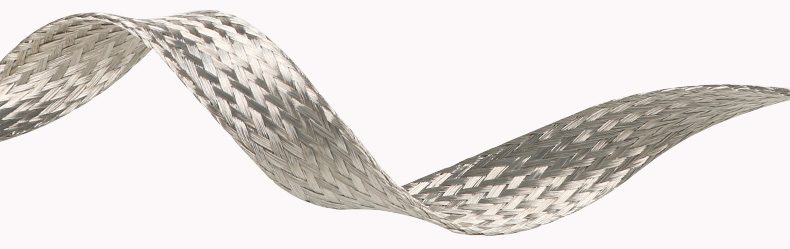

What is a flexible copper busbar?

Copper tinned busbars are fundamental components in electrical systems, designed for efficient power distribution.

These busbars consist of a copper core, known for its exceptional electrical conductivity, which is coated with a thin layer of tin to bolster its resistance to corrosion and enhance its solderability.

This fusion not only preserves the innate conductivity of copper but also extends the lifespan and reliability of the busbar.

Technical Parameter of copper tinned busbar

Material: T2 copper wire, copper content >99.95%

Surface treatment: bare copper, tin plating, nickel plating, silver plating

Monofilament diameter: 0.05mm (American wire gauge AWG44)

Model meaning

0.07mm(American wire gauge AWG41)

0.10mm(American wire gauge AWVG38)

0.12mm

0.127mm(American wire gauge AVVG36)

0.15mm(regular)

0.20mm(American wire gauge AWG32)

0.25mm

0.254mm (American wire gauge AVG 30)

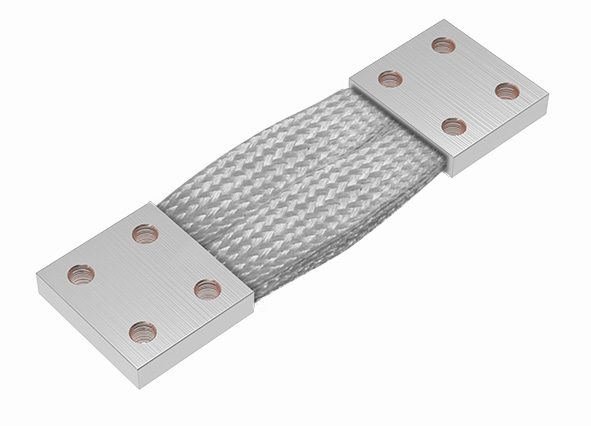

When placing your order, please specify the following values:

Cross-sectional area

Length(L)

Copper and hole type

Aperture(d)

Monofilament diameter (conventional 0.15mm)

The Process of copper tinned busbar

Selection and Preparation of Copper: High-purity copper is chosen for its superior conductivity and then shaped into bars.

Cleaning: The copper bars are thoroughly cleaned to remove any oxides and impurities, ensuring the tin adheres properly.

Tinning Process: The cleaned copper bars are then subjected to tinning, typically through electroplating or hot-dip tinning.

Electroplating involves passing an electric current through a tin solution with the copper busbar, depositing a layer of tin on its surface. Hot-dip tinning immerses the copper directly into molten tin, achieving a similar coating.

Finishing Touches: Following tinning, the busbars may undergo a final cleaning and smoothing process, ensuring the tin coating is even and free of defects.

Features of copper tinned busbar

Corrosion Resistance: The tin coating protects the copper from oxidizing, making it ideal for use in harsh environments.

Enhanced Solderability: Tin improves the copper’s ability to form soldered connections, facilitating easier assembly and repairs.

Durability: This added layer of protection ensures a longer operational life, reducing the need for frequent replacements.

High Conductivity: Despite the coating, the busbar maintains the high electrical conductivity characteristic of copper, ensuring efficient power distribution.

Advantages of copper tinned busbar

1、Enhanced Corrosion Resistance

Tin is inherently resistant to corrosion, especially in environments that are prone to high humidity or contain corrosive elements.

When applied to copper, it significantly extends the lifespan of the busbar by protecting it from such conditions.

2、Improved Solderability

Tin not only protects but also improves the copper’s ability to be soldered, making it easier to establish secure, low-resistance connections between components.

This is particularly valuable in complex electrical systems where reliability is paramount.

3、Lower Maintenance Needs

The durability and resistance to corrosion of copper tinned busbars translate to lower maintenance requirements.

This not only reduces operational costs but also minimizes downtime in critical applications.

4、Versatility

Thanks to their enhanced properties, copper tinned busbars can be used in a diverse range of environments and applications, from renewable energy systems and automotive electronics to power distribution in industrial settings.

5、The Impact on Industries

The introduction of copper tinned busbars is set to revolutionize several industries by providing a more reliable and efficient means of power distribution.

In renewable energy, for example, they offer a way to efficiently manage the fluctuating power output of solar panels and wind turbines.

In the automotive sector, particularly in electric vehicles (EVs), they provide a lightweight, efficient solution for managing high current flows, which is crucial for performance and battery life.

leave your question

Get your Comfortable Solution

![]()

GRL Electric Co., Ltd. is one of the leading companies in the Middle And High End market of low-voltage electric in China